My macro lens arrived to day! So here is a close up of the Sapphos sculpture printed at .2 mm. Even close up its not easy to make out the layers.

Sunday, 30 December 2012

Friday, 28 December 2012

Printable spool for Laywoo-D3 filaments.

I designed this spool specifically for the Laywoo-D3 filaments. This one

is actually printed in the Laywoo-D3 filament. Its a little bendy, and I

suggest printing in either ABS or PLA.

I also designed this to be printable on an UP printer (140x140mm) and with no support.

Centre hub is 30mm in diameter. And the arms are adjustable to suit either 1.75mm or 3mm.

The STL can be downloaded here

I also designed this to be printable on an UP printer (140x140mm) and with no support.

Centre hub is 30mm in diameter. And the arms are adjustable to suit either 1.75mm or 3mm.

The STL can be downloaded here

More fun with wood!

Thursday, 27 December 2012

Laywoo-D3 and support

I was asked how Laywoo-D3 prints with support. At that stage I had stuck with mainly models that didn't require support, as I was also quite dubious about how easy support might be to remove. Or how stable it might be during building, as it is quite soft.

I had been printing some Sapphos statues recently and wondered how well it might print in Laywoo-D3.

So here is the result!

I used a flash with these pictures as it highlights the details far better. At least until my new macro lens arrives.

I had been printing some Sapphos statues recently and wondered how well it might print in Laywoo-D3.

So here is the result!

I used a flash with these pictures as it highlights the details far better. At least until my new macro lens arrives.

You can see the support around the base and under the chin. There is also a bit at the back of the head that is not shown. I have been printing in .15mm layers, but thought I would do this in .2mm. The layers are just visable.

Although the support was stuck on well, it did generally come away cleanly.

One issue is the lightening of the areas where support was removed. Although the flash makes it look much worse than it is. I found just wetting my finger and rubbing over the are seem to help. Perhaps a clear coat might be worth a try.

And here is one printed at .15mm in ABS as a comparison.

Friday, 21 December 2012

End of the world? Nah, just some really neat coasters!

Thursday, 20 December 2012

New kapton tape, new price.

Just received our new shipment of 140mm wide kapton tape.

This lot is thicker than the first batch at .08mm, or just over 3 mil and due to a bulk purchase I have been able to reduce the price from $40 to $29 per 33M roll. That should yeild around 230 platform coverings at about 12.6c per cover.

This lot is thicker than the first batch at .08mm, or just over 3 mil and due to a bulk purchase I have been able to reduce the price from $40 to $29 per 33M roll. That should yeild around 230 platform coverings at about 12.6c per cover.

Wednesday, 12 December 2012

Laywoo-D3 update

After a total of around 8 hours of printing with the Laywoo-D3 with no blockages I'm fairly confident that the .5mm nozzle has done the trick. Enlarging the UP nozzle also hasn't seemed to have had a detrimental effect on ABS or PLA printing either!

Something I have learned is this material really likes plenty of air. Very much like PLA in this regard. Otherwise it has a tendency to become quite stringy.

I printed the terracotta warrior again but with maximum fill. This gave a pleasing weight to it. Much more like a real piece of wood, more so than the previous hollow print. The other thing I discovered is that the layer bonding is excellent, and the parts, although they flex a little, are very hard to break.

This is a tornado I printed at .15mm. Its a little furry.

Something I have learned is this material really likes plenty of air. Very much like PLA in this regard. Otherwise it has a tendency to become quite stringy.

I printed the terracotta warrior again but with maximum fill. This gave a pleasing weight to it. Much more like a real piece of wood, more so than the previous hollow print. The other thing I discovered is that the layer bonding is excellent, and the parts, although they flex a little, are very hard to break.

This is a tornado I printed at .15mm. Its a little furry.

Sunday, 9 December 2012

Wooden Warrior!

Well being all out of terracotta.....

My first test a few weeks ago with Laywoo-D3 wasn't so succesful on the UP. The nozzle quickly became blocked after about 15 min. So I abandoned further prints until I could get hold of a .5mm nozzle. In the end I bought some .5mm drill bits and enlarged a spare nozzle I had. Stock size is .4mm I think.

So today I tried printing out a scan of a terracotta warrior I scanned with 123D catch a few months back. The print took around 1 hour 22 min, significantly longer than any other print I had tried. I printed at .15mm layers and minimum fill, to save wood. The 1.7mm wood is rather rare at the moment.

The fact it printed without any blockages is hopefully due to the larger nozzle, but I could have just got lucky. More printing will tell I guess. But I successfully swapped back to ABS without any issues.

The wood is quite stringy, as you can see between the feet, kinda like PLA, but what I love is the wood feel of the object. It really feels like a piece of wood. In this case cardboard, due to being almost hollow. Its quite soft too, but I think it will harden up in a day or so. Also note the layers are almost completely invisible!

My first test a few weeks ago with Laywoo-D3 wasn't so succesful on the UP. The nozzle quickly became blocked after about 15 min. So I abandoned further prints until I could get hold of a .5mm nozzle. In the end I bought some .5mm drill bits and enlarged a spare nozzle I had. Stock size is .4mm I think.

So today I tried printing out a scan of a terracotta warrior I scanned with 123D catch a few months back. The print took around 1 hour 22 min, significantly longer than any other print I had tried. I printed at .15mm layers and minimum fill, to save wood. The 1.7mm wood is rather rare at the moment.

The fact it printed without any blockages is hopefully due to the larger nozzle, but I could have just got lucky. More printing will tell I guess. But I successfully swapped back to ABS without any issues.

The wood is quite stringy, as you can see between the feet, kinda like PLA, but what I love is the wood feel of the object. It really feels like a piece of wood. In this case cardboard, due to being almost hollow. Its quite soft too, but I think it will harden up in a day or so. Also note the layers are almost completely invisible!

Thursday, 6 December 2012

Nozzle too cold

There have been quite a few iterations of the "wind barrier" for the UP Plus printer, the latest of which is an adjustable flap to allow you to swap between air blowing over the print and not. The latest printers, so I am told, also have larger fans, which allow for even better cooling. Especially helpful during PLA printing.

Anyway, I've been occasionally getting "Nozzle too cold" errors when having the flap set to full open. It seems like the heater just can't keep up. So I thought I would try and do something to help insulate the element from the blowing air. What I have done is applied ( quite messily) high temperature silicone to the side and bottom of the heater element, but not the nozzle. I also applied it to the heater wires, that have a nasty tendency to break after a while, to help support them.

High temp silicone should be available at most auto parts stores.

So far so good! Even with the flap closed there is a small amount of air that escapes the barrier. This seemed enough to cool my hot end to about 98%. No problem really, its only when it gets to around 93 that it stops printing. So far the temp is reading 100% all the time, with or without the fan blowing on it. The other added benefit is that stray filament doesn't stick all over the heater making a nasty mess.

Anyway, I've been occasionally getting "Nozzle too cold" errors when having the flap set to full open. It seems like the heater just can't keep up. So I thought I would try and do something to help insulate the element from the blowing air. What I have done is applied ( quite messily) high temperature silicone to the side and bottom of the heater element, but not the nozzle. I also applied it to the heater wires, that have a nasty tendency to break after a while, to help support them.

High temp silicone should be available at most auto parts stores.

So far so good! Even with the flap closed there is a small amount of air that escapes the barrier. This seemed enough to cool my hot end to about 98%. No problem really, its only when it gets to around 93 that it stops printing. So far the temp is reading 100% all the time, with or without the fan blowing on it. The other added benefit is that stray filament doesn't stick all over the heater making a nasty mess.

Thursday, 29 November 2012

Christmas star

A customer recently sent me a photo of a star he printed for their Christmas tree.

Santa should have no trouble finding his way to this tree!

Printed with Crysta-Line Topaz on a Solidoodle 2 printer.

The files for this can be found at http://www.thingiverse.com/thing:14846

The same customer also sent me a logo he printed. Its a beaker with blue "liquid".

Santa should have no trouble finding his way to this tree!

Printed with Crysta-Line Topaz on a Solidoodle 2 printer.

The same customer also sent me a logo he printed. Its a beaker with blue "liquid".

Saturday, 24 November 2012

Lithonator....

Thought I might try something a little less "family" orientated.

You can download and print this yourself, although be warned, its a ~100mb file, so could take some slicing....

This was done at .15mm on an UP! (currently on special at $1499)

http://www.thingiverse.com/thing:34491

You can download and print this yourself, although be warned, its a ~100mb file, so could take some slicing....

This was done at .15mm on an UP! (currently on special at $1499)

http://www.thingiverse.com/thing:34491

Monday, 12 November 2012

Its Here! Photo to Mesh V3

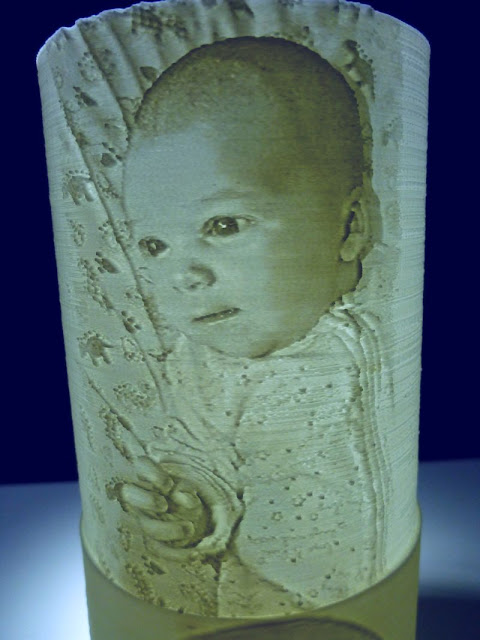

The new version of Photo to Mesh V3 is now here! What's so exciting you ask ? Well cylindrical lithophanes of course! Plus a host of other great new features.

Here are just a few examples of what I have printed over the last few days. All printed on an UP! printer at .15mm layer height.

This first one has 3 photos printed on the outside. Done by stitching 3 photos together then importing it as one new photo.

Lucky enough we just had our first baby boy just a few weeks ago, so I have the perfect subject.

A group shot.

Below is a print I made without any smoothing. I had falsely thought the printer wasn't capable of resolving the full detail, but I was stunned at just how good it could look. I now have to go back and print my earlier ones as they now look blurry in comparison.

Thanks Owen Ransen for all your hard work developing this great piece of software.

Here are just a few examples of what I have printed over the last few days. All printed on an UP! printer at .15mm layer height.

This first one has 3 photos printed on the outside. Done by stitching 3 photos together then importing it as one new photo.

Lucky enough we just had our first baby boy just a few weeks ago, so I have the perfect subject.

A group shot.

Below is a print I made without any smoothing. I had falsely thought the printer wasn't capable of resolving the full detail, but I was stunned at just how good it could look. I now have to go back and print my earlier ones as they now look blurry in comparison.

Be one of the first to own a copy. You can get it HERE

Thanks Owen Ransen for all your hard work developing this great piece of software.

Monday, 5 November 2012

Lithophanes revisited

Something very exciting is about to happen in the lithophane world. Stay tuned....

Sunday, 28 October 2012

1.7mm Wood has arrived!

I was pretty excited to receive my 1.7mm wood sample the other day. It looks really good. very flexible, to the point it is quite difficult to snap, unlike ABS.

I quickly put it in the UP and extruded at 200C. All looked good for a while, as I attempted to print out the cyclonic shape I printed with the Crysta-Line filaments. Anyway, after about 10 minutes the extruder blocked. Damn. Although when cleaning I discovered the tip hadn't blocked but the tube above had! Not sure why, as this is 2mm wide. I later discovered that it is also reccomended to use a nozzle of .5mm. I have a spare which I will drill out ( the stock Up nozzle is .35mm) and try again.

One thing I found was that due to the texture of the wood layers almost disappear.

Here is a picture of what I managed to print out.

I quickly put it in the UP and extruded at 200C. All looked good for a while, as I attempted to print out the cyclonic shape I printed with the Crysta-Line filaments. Anyway, after about 10 minutes the extruder blocked. Damn. Although when cleaning I discovered the tip hadn't blocked but the tube above had! Not sure why, as this is 2mm wide. I later discovered that it is also reccomended to use a nozzle of .5mm. I have a spare which I will drill out ( the stock Up nozzle is .35mm) and try again.

One thing I found was that due to the texture of the wood layers almost disappear.

Here is a picture of what I managed to print out.

Wednesday, 24 October 2012

Crysta-Line colours!

Here are some printed examples of the new Crysta-Line colour range.

Crysta-line Crystal Clear

Crysta-line Ruby Red

Crysta-line Topaz Blue

Crysta-line Amber Yellow

Stock expected 12th of November.

Crysta-line Crystal Clear

Crysta-line Ruby Red

Crysta-line Topaz Blue

Crysta-line Amber Yellow

Stock expected 12th of November.

Tuesday, 9 October 2012

New products in the Crysta-line range.

I just had a quick look at some samples of the new colours coming in the clear Crysta-line range.

For now the choices will be

Ruby red

Amber yellow

Sapphire blue

and the original clear.

Should be available in the next 2 weeks.

For now the choices will be

Ruby red

Amber yellow

Sapphire blue

and the original clear.

Should be available in the next 2 weeks.

Watch for splinters!

I received my sample of laywoo-D3 wood filament today. To say this stuff is weird wood (hehe) be an understatement! Unfortunately its only available in 3mm at present, and I can only print in 1.75mm.

Its very brittle, so its clear it would need quite a large reel. Or sold only as loose coil.

I plan on getting some for stock as soon as possible.

I got two samples, one is almost a chocolate brown, the other a tan. I believe the extruding temperature will effect the colour also. Higher temps result in darker wood.

Here's a pic..

UPDATE I should have some 1.7mm samples very soon!

Its very brittle, so its clear it would need quite a large reel. Or sold only as loose coil.

I plan on getting some for stock as soon as possible.

I got two samples, one is almost a chocolate brown, the other a tan. I believe the extruding temperature will effect the colour also. Higher temps result in darker wood.

Here's a pic..

UPDATE I should have some 1.7mm samples very soon!

Sunday, 7 October 2012

A sneak peak.

Here's a quick look at one of the new ABS filaments I'm working on. Should be available soon. Other colours coming too......

This is a rose bud sitting atop a torch. A bit hard to capture in a photo, but it looks pretty cool. I think if it was printed with less internal support it would look even better.

This is a rose bud sitting atop a torch. A bit hard to capture in a photo, but it looks pretty cool. I think if it was printed with less internal support it would look even better.

Wednesday, 3 October 2012

Monday, 1 October 2012

UP Plus Enclosure

I've been working on this on and off for a few months, and I think its finally ready for prime time.

After having quite a few larger prints fail due to warping and delamination I decided to build an enclosure. The biggest problem was keeping the print area hot, but not overheating the electronics. Many designs for enclosures I had seen also enclose the electronics housed at the bottom. Not ideal. The unrestricted access to the air vents on the sides in this design leaves the electronics unaffected.

By not using active heating I feel I have come to a good compromise between reducing issues, and not creating new ones. Although I would like to get the chamber up to ~65 C during printing, this is just not an option with the extruder stepper motor inside. The thermal limit of which is 80C and normally runs around 30 C above ambient.

To keep the extruder temp under control I have mounted 2 40mm heatsinks and fans. On testing I found just one kept the temperature at 60C . So 2 should improve on this.

I settled on this design, after a few experimental builds. I wanted something that would compliment the UP Plus's looks, and yet still stay compact, and thanks to the handle on top, very portable.

All the mounting parts, handles and hinges are printed on the UP. While this allows for easy repairs and modifications it also keeps the costs down. Hey isn't this what 3D printers are for?

If there is enough interest I'm going to have a batch cut and powder coated red.

Contact me if you want one.

Here's an earlier prototype.

Friday, 28 September 2012

UP! - Grade coming

Some exciting news. PP3DP, the makers of the UP! printers have announced there will be a new version of their software released on the 30th of September. The two major changes will be the ability to print thinner walls than previous, and the one that interests me most, a reduction in layer thickness! The UP! Plus will go from a minimum of 0.2mm to 0.15mm and the new MINI will go from 0.25mm to 0.2mm. I'm sure there will be other changes, but we have to wait a few more days yet....

|

| A ring printed at the new higher resolution. (I get the Opera House, and Sydney Harbour Bridge, but is that a beer bottle at the back??) |

Tuesday, 25 September 2012

Holy lithomania batman!

It turns out that making the picture as a negative yields a much better result!

These are called lithophanes, and used to be made from porcelain, but work equally well in plastic!

I'm using the program Photo to Mesh to lift a 3D picture from a 2D photo. There are a few programs out there that will do the same, but this one was cheap and easy to use. A free demo is available too.

Here are a couple samples I have done. Printed in white plastic .

These are simply held up the light to show the detail. The tops get a little rough because they are printed vertically, and the print tends to wobble around a bit as it gets higher. The thinnest parts are .6mm so its not a surprise.

Here is what the puppy looks like without backlight.

These are called lithophanes, and used to be made from porcelain, but work equally well in plastic!

I'm using the program Photo to Mesh to lift a 3D picture from a 2D photo. There are a few programs out there that will do the same, but this one was cheap and easy to use. A free demo is available too.

Here are a couple samples I have done. Printed in white plastic .

These are simply held up the light to show the detail. The tops get a little rough because they are printed vertically, and the print tends to wobble around a bit as it gets higher. The thinnest parts are .6mm so its not a surprise.

Here is what the puppy looks like without backlight.

Thursday, 20 September 2012

Came across a program called Photo to Mesh that lifts a 3D image from a 2D photo.

Here is the original photo, converted to grey scale.

First print in white. Pity about the lines, but I might be able to reduce them....

This one is printed in the new Crysta-line clear ABS found here I'm really happy with how this came out. Its printed really thin and allows the light to create a fantastic effect.

Here is the original photo, converted to grey scale.

First print in white. Pity about the lines, but I might be able to reduce them....

This one is printed in the new Crysta-line clear ABS found here I'm really happy with how this came out. Its printed really thin and allows the light to create a fantastic effect.

Thursday, 6 September 2012

Clear update

Here are a couple shots of a 0.8mm thick(this is as thin as my printer will allow) rectangle, one printed at 270C the other at approximately 240C.

The results are not what I expected at all. I had expected the higher temp would produce a clearer print, but it doesn't. It seems to be more crystal like. Strength is about the same for both pieces, which I think is better than other filaments I have used, but I'll hold judgement until I do direct comparisons. Certainly the bare filament takes far more to break from bending than normal.

I also tried sanding a piece with 1200 grit and then rubbing with acetone, but this didn't have any real effect on the transparency, but it did make the layers a little less defined.

The results are not what I expected at all. I had expected the higher temp would produce a clearer print, but it doesn't. It seems to be more crystal like. Strength is about the same for both pieces, which I think is better than other filaments I have used, but I'll hold judgement until I do direct comparisons. Certainly the bare filament takes far more to break from bending than normal.

This first one was printed at ~240C

High temperature 270C

The liquid paper test!

Clearly better ( pun intended)

I also tried sanding a piece with 1200 grit and then rubbing with acetone, but this didn't have any real effect on the transparency, but it did make the layers a little less defined.

Wednesday, 5 September 2012

Gone fishing...

My eagerly awaited clear ABS sample arrived today! First thing I thought was they had sent me fishing line! The filament is very smooth and seems like it is of high quality. Measured filament thickness was a very consistant 1.74mm. It was also packaged nicely in a vacuum sealed foil bag.

So how does it print ? It appears to print very well. I've only printed a tornado shaped object, but it came out well with no bubbles and quite transparent. The other thing I noticed was its strength. I'll need to print the same thing in a colour to do a true A/B test, but the walls seemed unusually strong for 0.8mm

How it came.

The fishing line.

The first print.

Transparency.

So how does it print ? It appears to print very well. I've only printed a tornado shaped object, but it came out well with no bubbles and quite transparent. The other thing I noticed was its strength. I'll need to print the same thing in a colour to do a true A/B test, but the walls seemed unusually strong for 0.8mm

How it came.

The fishing line.

The first print.

Transparency.

Subscribe to:

Posts (Atom)